Blog Post

Swivel Joint Fundamentals

Jun. 8, 2022

Dixon entered the industrial swivel market in 1985 when it acquired Le-Hi Andrews. Over the years, working with our engineers, foundry, and extensive CNC machine shop, we have refined and expanded our swivel product line to better meet the needs of our customers.  Wherever stationary pipes and hoses must be plumbed to rotating machine parts, swivel joints provide a means of ensuring a reliable liquid-tight connection while allowing freedom of movement between system components. Swivels create a rotary mechanical and hydraulic linkage between stationary pipes, hoses, and other components of fluid transfer systems. They absorb shock, eliminate hose twisting and kinking, and allow for independent movement while fluids are pumped under pressure.

Wherever stationary pipes and hoses must be plumbed to rotating machine parts, swivel joints provide a means of ensuring a reliable liquid-tight connection while allowing freedom of movement between system components. Swivels create a rotary mechanical and hydraulic linkage between stationary pipes, hoses, and other components of fluid transfer systems. They absorb shock, eliminate hose twisting and kinking, and allow for independent movement while fluids are pumped under pressure.

Swivel joints prevent kinks that form in hoses when one end of the hose rotates opposite the other end. Hose kinking reduces flow, increases system pressure, and causes fatigue of hose walls, crimps, and end connectors. Over time, higher pressures and worn-out hoses increase the probability of unexpected system failures and the release of potentially hazardous chemicals.

Where Are Swivels Used?

Dixon swivel joints can be found in product blending plants, liquid, and dry bulk transfer terminals, and in transport trucks designed to carry petroleum and other liquids from bulk terminals to distant delivery sites. Additional industries range from petroleum and petrochemical plants to refining, mining, distilling, paint manufacturing, irrigation, fertilizing, and food and beverage processing. Larger diameter swivel joints can be found in steel mills, water treatment plants, and marine terminals where they are used for loading and discharging cargo, and for loading propulsion fuel onto vessels – a process known as bunkering.

If an industrial operation involves pumping a fluid from a moving component to a stationary component, chances are good that a swivel joint has been installed to extend the life of the system and reduce costly maintenance and downtime.

What are Swivel Joints?

Most swivels are composed of two main parts (split flange swivels are slightly different). These parts are known as the sleeve and the body. The sleeve and the body each have a means of connecting with the fluid transfer system - such as threads or a bolted flange. The sleeve and body are locked in place by one or more ball bearing races.

The ball bearing races keep the swivel sleeve and body aligned and allow the swivel to rotate around its axis. Because the two parts of the swivel can rotate, system components connected to the two ends of the swivel can also rotate freely and independently around the swivel's axis. Multiple swivels installed with different orientations allow multiple axes of rotation and more freedom of movement between two sides of a fluid conveyance system. Bearing races can be filled with different types of lubricants, including grease which is formulated for food applications. Bearing races can also be prepared for submerged service in a variety of fluid media.

Though the swivel's ball bearings do most of the mechanical work, the most important part of the swivel joint is arguably the liquid-tight pressure seal that retains the pressurized working fluid. Pressure seals can be made from thermoplastics such as PTFE, and from elastomers such as FKM and nitrile rubber. The properties of these seal material options make them suitable for service with various fluids over a range of operating temperatures.

Are There Different Types of Swivels?

Yes! There are three main categories of swivel joints:

- O-Ring Swivel Joints use an O-ring for the pressure seal. These are generally more compact and rotate more freely than a V-ring swivel joint.

- V-Ring Swivel Joints use a triple V-ring packing for the pressure seal. These are robust swivel joints generally used in more severe applications. V-ring swivel joints typically handle higher moment loads than O-ring swivel joints and the seals are self-adjusting which typically allows for longer seal life.

- Split Flange Swivel Joints use a separate bearing pack design along with an H-ring with two O-rings for the pressure seal. Split flange swivels are equivalent to O-ring swivel joints in terms of required torque to turn, but have a load capacity comparable to V-ring swivel joints. Additionally, split flange swivel joints are more serviceable due to their easily accessible pressure seal and bearing packs.

Dixon swivel joints are available in a wide range of sizes and end configurations. Depending on the type of swivel sizes range from 1" through 12" and materials include brass, aluminum, malleable iron, 316 stainless steel, and carbon steel. End configurations include weld end, threaded, ASME, and TTMA flanges.

How Does Dixon Number its Swivel Joints?

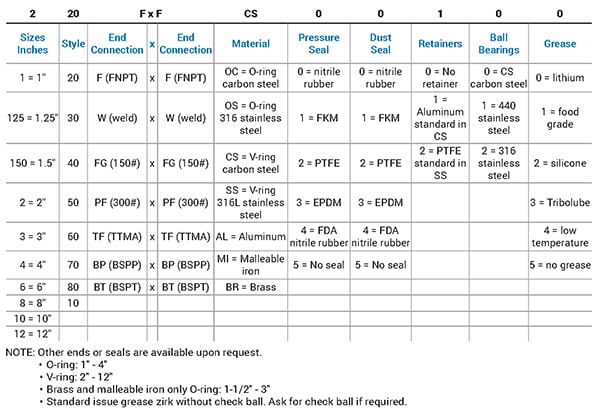

Dixon's part numbering system is easy to understand using the part number grid available in the Dixon Product List (DPL), our swivel joint catalog, and on the website. O-ring and V-ring swivel joints use the same system and are differentiated in the material call out:

- The first 1 to 3 characters reference the size.

- The next 2 characters reference the style which indicates the elbow configurations and the number of planes of rotation.

- The next 3 to 5 characters indicate the end connections like FNPT (Female National Pipe Thread) threads or 150# flanges.

- The following 2 characters indicate the material as well as whether or not the swivel joint is an O-ring or V-ring. An example would be that OC represents an O-ring swivel in carbon steel while CS is a V-ring swivel in carbon steel.

- The last 5 characters are all codes that indicate the pressure seal, dust seal, and retainer material for the V-ring, ball-bearing material, and grease requirements. Split flange swivel joint part numbers are similar, however, they always begin with the prefix SF.

O-ring and V-ring Swivel Join Number System

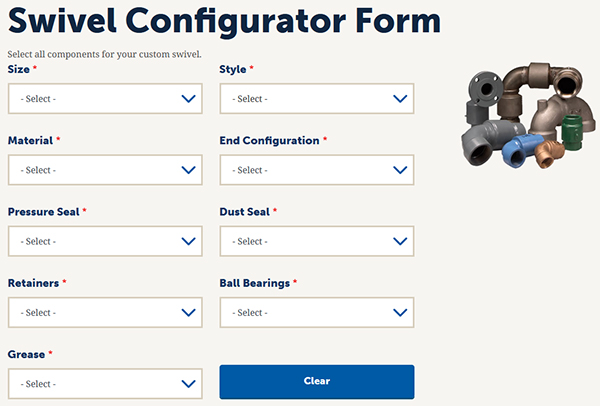

Dixon's Swivel Configurator Tool

Dixon’s Swivel Configurator tool is intuitive if you already know what swivel joint is needed for your application. You can simply make the appropriate selections for each field on the form to create the swivel joint part number that matches that description.

For any requests for swivel joints that are not captured with the standard options in the selectable fields please contact us at 888.226.4673.

Questions?

If you have any questions about swivel joints or how to select the right component, reach out to a Dixon specialist.

AU | en

AU | en